| live chat |

|

Welcome to our site, if you need help simply reply to this message, we are online and ready to help.

12:10

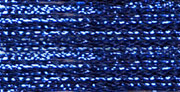

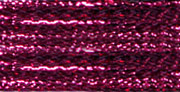

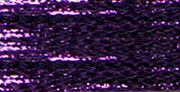

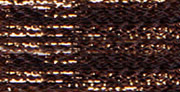

We are engaged in manufacturing high quality metallic yarn in various textures of viscous, polyester, and other. These are used in textile industry in knitting, suiting fabrics, weaving, embroidery, jeans, cotton fabrics, and in many other items. We offer a wide variety of metallic yarn that includes silver metallic, rayon metallic, and gold metallic yarn. These are available at market leading prices.

We are one of the leading manufacturers of excellent quality coated polyester film. These are metallic yarn having high tensile strength and colorfastness and have been processed using pinhole free metallizing process virtue of which they provide high productivity at the time of micro slitting. These are used for weaving, knitting and embroidery. Coated polyester films are available in wide variety of colours and range such as coated film for metallic yarn, matt finish film, high slip film for glitter powder and tracing & drafting film.

| Thickness (micron) | Width (inch) | Length (meter per kg)X1000 | Composition | ||||

|---|---|---|---|---|---|---|---|

| Silver | Gold | Color | Clear | Irise | |||

| 12 | 1/32" | 73 | 67 | 65 | 80 | PE 100% | |

| 1/50" | 109 | 101 | 99 | ||||

| 1/69" | 146 | 135 | 131 | 160 | |||

| 1/100" | 219 | 203 | 198 | 240 | |||

| 1/110" | 236 | 219 | 213 | 257 | |||

| 1/127" | 274 | 270 | 268 | ||||

| 25 | 1/32" | 37 | 36 | 35 | PE 100% | ||

| 1/69" | 73 | 71 | 70 | ||||

| 1/92" | 102 | 98 | 97 | ||||

| 1/100" | 110 | 106 | 105 | ||||

| 30 | 1/32" | 35 | |||||

| 1/69" | 70 | ||||||

| 1/100" | 105 | ||||||

| 38 | 1/32" | 25 | 24 | 23 | 30 | ||

| 1/69" | 49 | 48 | 47 | 60 | |||

| 1/100" | 74 | 72 | 89 | ||||

| TESTS | TEST CONDITIONS | RESULTS |

|---|---|---|

| Laundry | 40°C, 20min., Household laundry | |

| Chemical Cleaning | 25°C, 30min., Perchlorethylene | |

| 25°C, 30min., Tetracholoroethylene | ||

| 25°C, 30min., Petroleum Benzine | ||

| Ironing | 135°C, 15sec. | |

| Hot water | 80°C, 30min. | |

| Steam | 100°C, 30min., for silver. | |

| 70°C, 40min., for gold & all colours. | ||

| Dry heating | 180°C, 60sec. | |

| Scouring for nylon, polyester, rayon, acetate & cotton | Soap 0.5gr/liter, Soda Ash 0.5gr/loter, 80°C, 30min. | |

| Souring for wool | Monogen 5gr/liter, 60°C, 30min. | |

| Overdyeing wool, nylon & acetate | Acetic Acid 0.5gr/liter, 80°C, 30min. | |

| Bleaching | sodium Hydrosulfite 2gr/liter, 80°C, 60min. | |

| Soda Ash 0.5gr/liter, 80°C, 60min. | ||

| ph9 30% Hydrogen Peroxide 40gr/liter, 70°C, 60min. | ||

| ph9 10% Sodium Hydrochlorite 40gr/liter, 70°C, 60min. | ||

| Finishing | ph9 Sodium Carbonate 95°C, 60min. | |

| Mongen 5gr/liter, Oxalic Acid 10gr/liter Acetic Acid 10gr/liter, 45°C, 20min. | ||

| Caustic Soda | 28Be 21°C, 60sec. |

Above figures are not guaranteed specifications but tested data by our laboratory.

Avoid all procedures in acidic and alkalic enviroments even if trials give acceptable result.

GAYLORD PACKERS supplies special yarns for special application.

Due to the peculiarity of metallic yarn, we suggest that all these data to be carefully examined before your actual production.

| Width (inch) | Supported with (denier) | Length (meter per kg)X1000 | Composition | ||||

|---|---|---|---|---|---|---|---|

| Silver | Gold | Color | Clear | 30mic IRIS | |||

| 12 MIC | |||||||

| 1/69" | 2X15d | 98 | 93 | 92 | 67% PE, 33% NY/PE | ||

| 2X20d | 88 | 84 | 83 | 93 | 53 | 61% PE, 39% NY/PE | |

| 2X30d | 74 | 70 | 69 | 47 | 51% PE, 49% NY/PE | ||

| 1/100" | 2X15d | 126 | 120 | 119 | 58% PE, 42% NY/PE | ||

| 2X20d | 112 | 108 | 106 | 116 | 71 | 50% PE, 50% NY/PE | |

| 1/110" | 2X15d | 130 | 126 | 56% PE, 44% NY/PE | |||

| 2X20d | 117 | 112 | 110 | 48% PE, 52% NY/PE | |||

| 25 MIC | |||||||

| 1/69" | 2X20d | 55 | 52 | 51 | 76% PE, 24% NY/PE | ||

| 60 | |||||||

| 1/100" | 91 | 61% PE, 39% NY/PE | |||||

| TESTS | TEST CONDITIONS | RESULTS |

|---|---|---|

| Laundry | 40°C, 20min., Household laundry | |

| Chemical Cleaning | 25°C, 30min., Perchlorethylene | |

| 25°C, 30min., Tetracholoroethylene | ||

| 25°C, 30min., Petroleum Benzine | ||

| Ironing | 135°C, 15sec. | |

| Hot water | 80°C, 30min. | |

| Steam | 100°C, 30min., for silver. | |

| 70°C, 40min., for gold & all colours. | ||

| Dry heating | 180°C, 60sec. | |

| Scouring for nylon, polyester, rayon, acetate & cotton | Soap 0.5gr/liter, Soda Ash 0.5gr/loter, 80°C, 30min. | |

| Souring for wool | Monogen 5gr/liter, 60°C, 30min. | |

| Overdyeing wool, nylon & acetate | Acetic Acid 0.5gr/liter, 80°C, 30min. | |

| Bleaching | sodium Hydrosulfite 2gr/liter, 80°C, 60min. | |

| Soda Ash 0.5gr/liter, 80°C, 60min. | ||

| ph9 30% Hydrogen Peroxide 40gr/liter, 70°C, 60min. | ||

| ph9 10% Sodium Hydrochlorite 40gr/liter, 70°C, 60min. | ||

| Finishing | ph9 Sodium Carbonate 95°C, 60min. | |

| Mongen 5gr/liter, Oxalic Acid 10gr/liter Acetic Acid 10gr/liter, 45°C, 20min. | ||

| Caustic Soda | 28Be 21°C, 60sec. |

Above figures are not guaranteed specifications but tested data by our laboratory.

Avoid all procedures in acidic and alkalic enviroments even if trials give acceptable result.

GAYLORD PACKERS supplies special yarns for special application.

Due to the peculiarity of metallic yarn, we suggest that all these data to be carefully examined before your actual production.

| Width (inch) | Supported with (denier) | Length (meter per kg)X1000 | Composition | ||||

|---|---|---|---|---|---|---|---|

| Silver | Gold | Color | Clear | 30mic IRIS | |||

| 1/110" | 1X75 RN | 80 | 78 | 76 | 76 | 56 | 34% PE 66% RN |

| 1X75 PE | 80 | 78 | 76 | 76 | 56 | 100% PE | |

| 1X70 NY | 83 | 81 | 79 | 37% PE 63% NY | |||

| TESTS | TEST CONDITIONS | RESULTS |

|---|---|---|

| Laundry | 40°C, 20min., Household laundry | |

| Chemical Cleaning | 25°C, 30min., Perchlorethylene | |

| 25°C, 30min., Tetracholoroethylene | ||

| 25°C, 30min., Petroleum Benzine | ||

| Ironing | 135°C, 15sec. | |

| Hot water | 80°C, 30min. | |

| Steam | 100°C, 30min., for silver. | |

| 70°C, 40min., for gold & all colours. | ||

| Dry heating | 180°C, 60sec. | |

| Scouring for nylon, polyester, rayon, acetate & cotton | Soap 0.5gr/liter, Soda Ash 0.5gr/loter, 80°C, 30min. | |

| Souring for wool | Monogen 5gr/liter, 60°C, 30min. | |

| Overdyeing wool, nylon & acetate | Acetic Acid 0.5gr/liter, 80°C, 30min. | |

| Bleaching | sodium Hydrosulfite 2gr/liter, 80°C, 60min. | |

| Soda Ash 0.5gr/liter, 80°C, 60min. | ||

| ph9 30% Hydrogen Peroxide 40gr/liter, 70°C, 60min. | ||

| ph9 10% Sodium Hydrochlorite 40gr/liter, 70°C, 60min. | ||

| Finishing | ph9 Sodium Carbonate 95°C, 60min. | |

| Mongen 5gr/liter, Oxalic Acid 10gr/liter Acetic Acid 10gr/liter, 45°C, 20min. | ||

| Caustic Soda | 28Be 21°C, 60sec. |

Above figures are not guaranteed specifications but tested data by our laboratory.

Avoid all procedures in acidic and alkalic enviroments even if trials give acceptable result.

GAYLORD PACKERS supplies special yarns for special application.

Due to the peculiarity of metallic yarn, we suggest that all these data to be carefully examined before your actual production.

| Type | Covered WITH (Denier) | Length(meter per kg)X1000 | Composition | ||

|---|---|---|---|---|---|

| Silver | Gold | Color | |||

| SMT-50NY/RN | 1X50 NY | 83 | 83 | --- | 54% PE 46% NY |

| SMT-70NY/RN | 1X70 NY | 66 | 66 | --- | |

| SMT-110NY/RN | 1X110 NY | 48 | 48 | 48 | 45% PE 55% NY |

| SMT-140NY/RN | 1X140 NY | 39 | 39 | 39 | 39% PE 61% NY |

| SMT-150 | 1X150 RN | 38 | 38 | 38 | 36% PE 64% RN |

| SMT-250 | 1X250 RN | 25 | 25 | 25 | 31% PE 69% RN |

| SMT-450 | 1X450 RN | 15 | 15 | 15 | 25% PE 75% RN |

| SMT-900 | 1X900 RN | 8 | 8 | 8 | 16% PE 84% RN |

| TESTS | TEST CONDITIONS | RESULTS |

|---|---|---|

| Laundry | 40°C, 20min., Household laundry | |

| Chemical Cleaning | 25°C, 30min., Perchlorethylene | |

| 25°C, 30min., Tetracholoroethylene | ||

| 25°C, 30min., Petroleum Benzine | ||

| Ironing | 135°C, 15sec. | |

| Hot water | 80°C, 30min. | |

| Steam | 100°C, 30min., for silver. | |

| 70°C, 40min., for gold & all colours. | ||

| Dry heating | 180°C, 60sec. | |

| Scouring for nylon, polyester, rayon, acetate & cotton | Soap 0.5gr/liter, Soda Ash 0.5gr/loter, 80°C, 30min. | |

| Souring for wool | Monogen 5gr/liter, 60°C, 30min. | |

| Overdyeing wool, nylon & acetate | Acetic Acid 0.5gr/liter, 80°C, 30min. | |

| Bleaching | sodium Hydrosulfite 2gr/liter, 80°C, 60min. | |

| Soda Ash 0.5gr/liter, 80°C, 60min. | ||

| ph9 30% Hydrogen Peroxide 40gr/liter, 70°C, 60min. | ||

| ph9 10% Sodium Hydrochlorite 40gr/liter, 70°C, 60min. | ||

| Finishing | ph9 Sodium Carbonate 95°C, 60min. | |

| Mongen 5gr/liter, Oxalic Acid 10gr/liter Acetic Acid 10gr/liter, 45°C, 20min. | ||

| Caustic Soda | 28Be 21°C, 60sec. |

Above figures are not guaranteed specifications but tested data by our laboratory.

Avoid all procedures in acidic and alkalic enviroments even if trials give acceptable result.

GAYLORD PACKERS supplies special yarns for special application.

Due to the peculiarity of metallic yarn, we suggest that all these data to be carefully examined before your actual production.